|

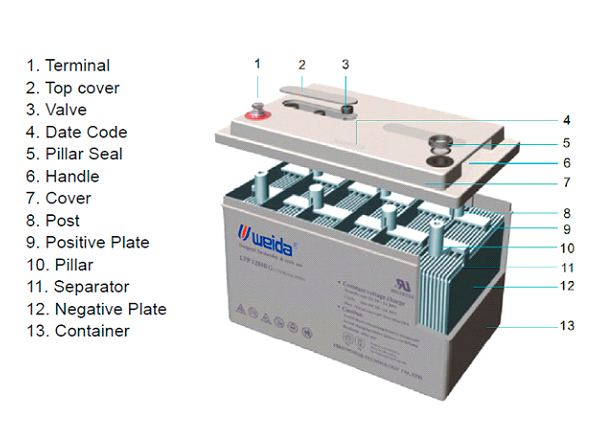

1.Features of WEIDA VRLA(AGM) Battery1.1 Nonspillable The WEIDA VRLA battery uses an absorbe delectrolyte system. All of the electrolyte is absorbed into the positive plates, negative plates, and the separators. Coupled with the use of special sealing epoxies, and long sealing paths for posts, WEIDA VRLA batteries have exceptional high leak resistance, and can be used in any position. 1.2 Sealed and Maintenance-free Operation There is no corrosive gas generation during normal use and no need to check the specific gravity of the electrolyte or to add water during the service life. 1.3 High Quality and High Reliability The WEIDA VRLA battery has stable and reliable capacity. The battery can withstand overcharge, over discharge, vibration, and shock. To assure this high quality and reliability, the batteries are 100% tested on production line for voltage, capacity, seals and the safety valve are 100% visually inspected before the final assembly process. 1.4 Exceptional Deep Discharge Recovery WEIDA batteries have exceptional deep discharge recovery and charge acceptance, even after deep or prolonged discharge. 1.5 Low Self-discharge Because of lead calcium grids alloy and highly purity materials, WEIDA VRLA battery can be stored for long periods of time without recharge. The rate of WEIDA VRLA battery self-discharge on open circuitis less than 2% per month at 20℃ /68 ℉ . 1.6 Long Service Life The WEIDA VRLA battery has long life instand by or cyclic service. 1.7 Solid Copper Terminals Ensures highest current carrying capability. 1.8 Computer-aided Design and Manufacturing Ensures quality products through control of processes and standards. 1.9 UL and CE . UL approval, file No. MH45805 CE approval, file No. TB13086276 2. Battery Construction

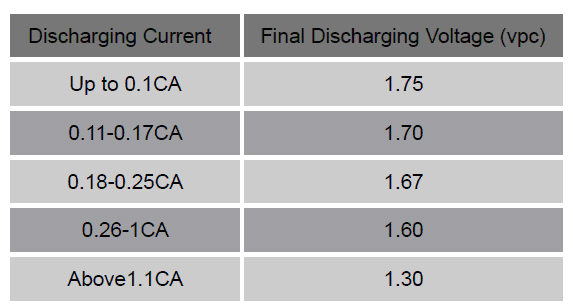

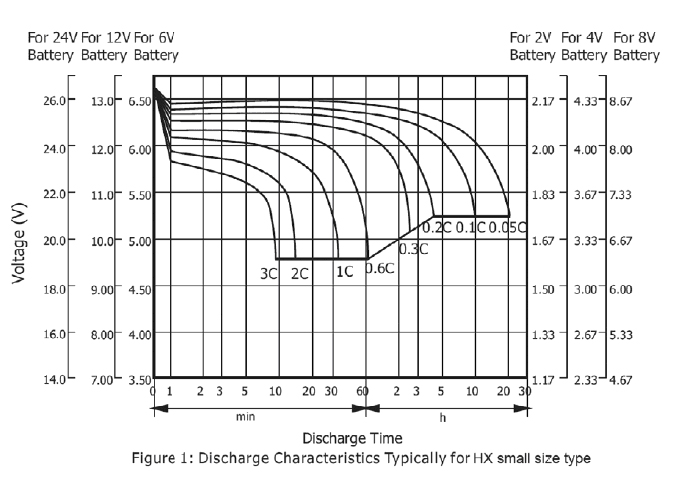

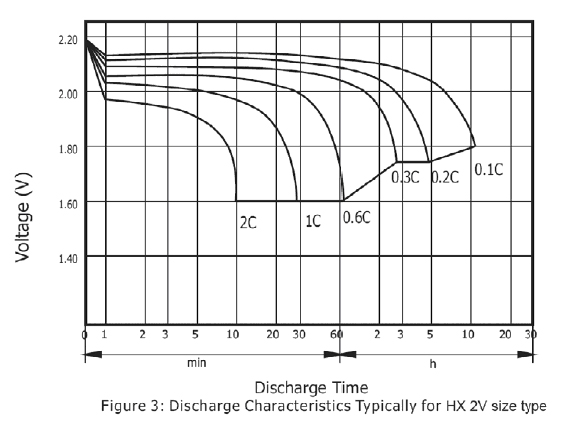

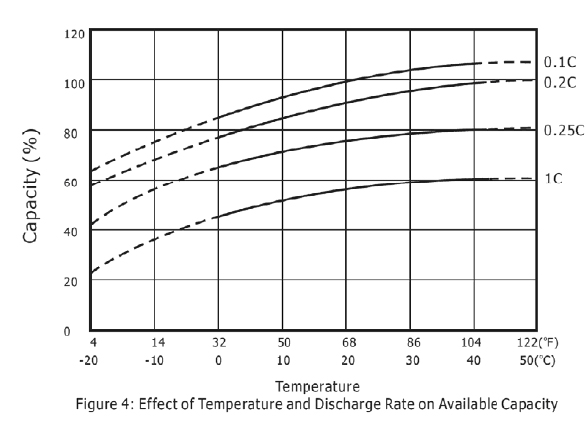

3.Characteristics of Discharging

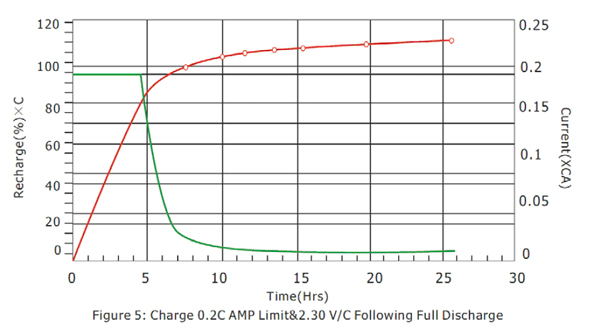

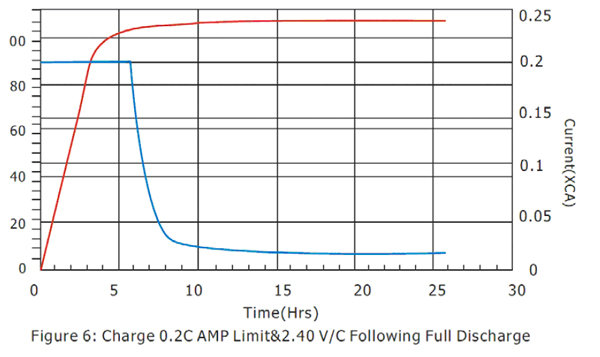

4.Characteristics of Charging4.1 Charging Methods Correct charging is very important factor to consider when using valve regulated lead acid batteries. Battery performance and service life will be directly affected by the charging methods. There are four major methods of charging: Constant voltage charging. Constant current charging. Two stages constant voltage charging. Taper current charging. 4.1.1 Constant Voltage Charging This is the recommended method of charging for VRLA batteries. It is necessary to closely control the actual voltage to ensure that it is with the limits advised. Standby service: 2.23-2.30 vpc at 20℃ (68℉ ) to 25℃ (77℉ ) Cycle service: 2.40-2.50 vpc at 20℃ (68℉ ) to 25℃ (77℉ ) It is suggested that the initial current be set within 0.4CAmps. Figure 5 and 6 indicate the time taken to fully recharge the battery. It is also seen that the charging current is decreased to approx 0.5-4mA/Ah under charging voltage 2.30 vpc, and 3-10mA/Ah under charging voltage 2.40vpc when the battery is fully charged at 20℃ (68℉ ) to 25℃ (77℉ ).

Note: it is necessary to ensure that the voltage is correctly set. The charging voltage set too high will increase the corrosion of the positive plates causing loss of capacity and ultimately shortening the life of the battery. 4.1.2 Constant Current Charging This method of charging is generally not recommended for VRLA batteries. It is necessary to understand that if the batteries are not removed from the charger as soon as possible after reaching a state of full charge. Considerable damage will occur to the batteries due to over charging. The required recharged capacity is 1.07 to 1.15 times as discharged capacity. 4.1.3 Two Stages Constant Voltage Charging This method should not be used where the battery and load are corrected in parallel, however, if this method is to be used, it is suggested that the WEIDA technicaldepartment be contacted. 4.1.4 Taper Current Charging This method is not recommended for VRLA batteries, however, if this method is to be usedit is suggested that the WEIDA technical department be contacted. 4.2 Effect of Temperature on Charging Voltage As temperature rises, electrochemical activity in the battery increases. Similarly, as temperature falls, electrochemical activity decreases. Therefore, as temperature rises, charging voltage should be reduced to prevent overcharge, as temperature falls, charging voltage should be increased to avoid undercharge. In general, to assure optimum service life, use of a temperature compensatedcharger is recommended. The recommended compensation factor for WEIDA VRLA batteries is ±3mV/℃. Cell (standby use) and±4mV/℃ cell(cyclic use). The standard central point for temperature compensation is 20℃ /68℉ . Figure7 shows the relationship between temperatures and charging voltages in both cyclic and standby applications.

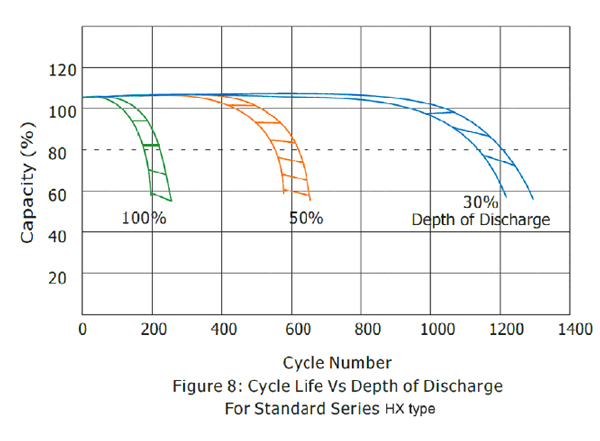

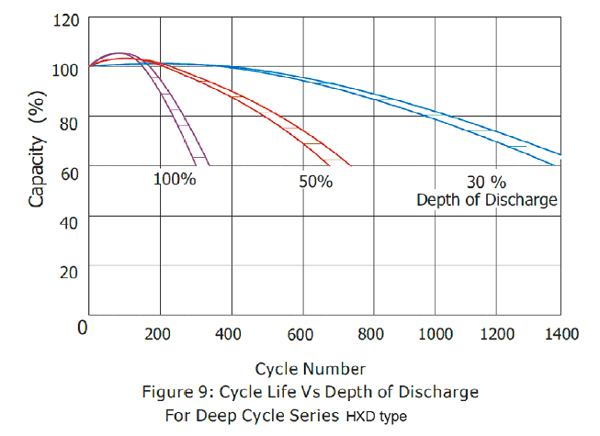

4.3 Charging Time The time required to complete each charge depends on the discharge condition of battery, characteristics of charge used, or the temperature during charge. For cyclic use, using constant voltage charging, this time can be estimated by the following expression at 25℃ /77℉ . ( 1 )Discharge current: Larger than 0.25CA Tch = Cdis/I + 3 ~5 ( 2 )Discharge current: Less than 0.25CA Tch = Cdis/I + 6 ~10 Tch: time required for charge (hours) Cdis: ampere-hour discharged before charge started(Ah) I : initial charging current(A). Complete charge time for float service will be slightly more than 24 hours. Note: The minimum recharge capacity should be 1.02~1.05 times of discharge capacity 5.Battery LifeBattery life depends on a number of key factors. These include: Operating temperature of the battery; Method of charging utilized; Actual use of the product i.e.: standby or cycle service etc. 5.1 Cyclic Life Given the above factors, the actual life of a battery in cycle service is dependent on the depth of discharge of each cycle. The greater the depth of discharge of each cycle, the less the number of cycles available from the battery.

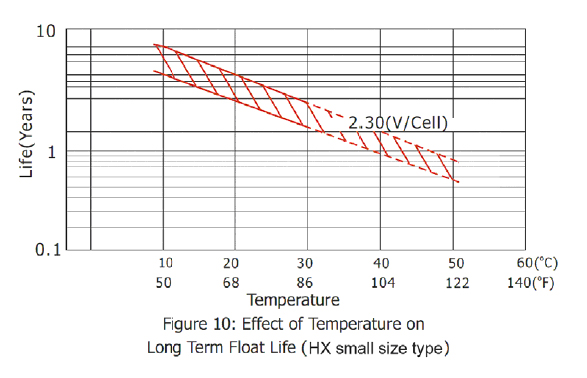

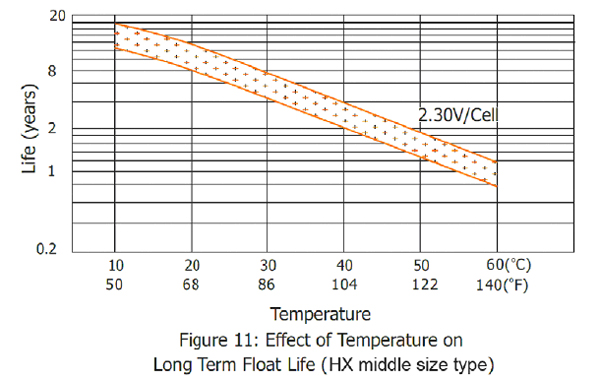

5.2 Standby Life The estimated life under float service of HX small size type is 7 years at 20℃/68℉; HXmiddle size type is 12years at 20℃/68 ℉;HX 2V size type is more than 20 years at 20℃/68℉. The float service life is affected by the factors listed above and the number of discharging, the depth of discharging the battery suffers during its life time. The more discharges suffered and thedeeper the discharges, the shorter the battery life. The higher the temperature, the shorter the battery life. If the battery temperature remains at an elevated level for an extended period of time, the expected life is reduced by 50% for each 8 to 10℃ of constant temperature above 20℃ /68℉.

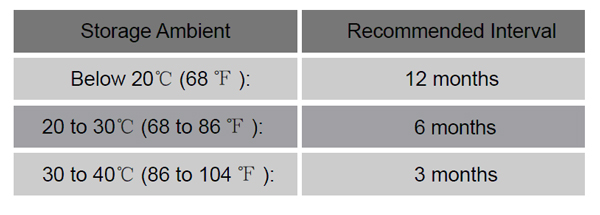

6.Battery Storage6.1 General Storage Conditions: The battery should be stored under the following conditions. (1) Low humidity (2) 5 to 122 ℉ (-15 to 50℃ ) (3) Clean, and avoid direct sunlight. 6.2 Capacity after Long Term Storage After long term storage, all batteries deliver less than rated capacity on first cycle. In cyclic application, full capacity may be obtained through several charge/discharge cycles, typically 2-3 cycles. 6.3 Refresh Charge When batteries are placed in extended storage, it is recommended that they receivea refresh charge at recommended intervals as following; Refresh charging method: 3 to 5 hours of constant current 0.1C Amps or 12 to 16 hours at constant voltage of 2.45V/cell.

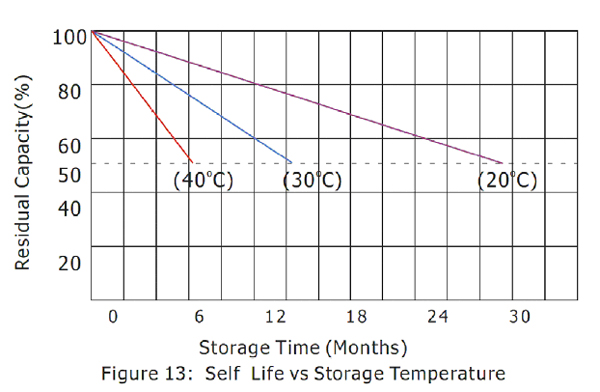

6.4 "Self Life"- typical capacity vs. time Self-discharge rate is very much dependent on the storage temperature as shown in Figure 13.Lower temperatures allow the battery to be stored for longer periods. (Each ten degree centigrade drop results in a halving of self-discharge rate and doubles storage time.)

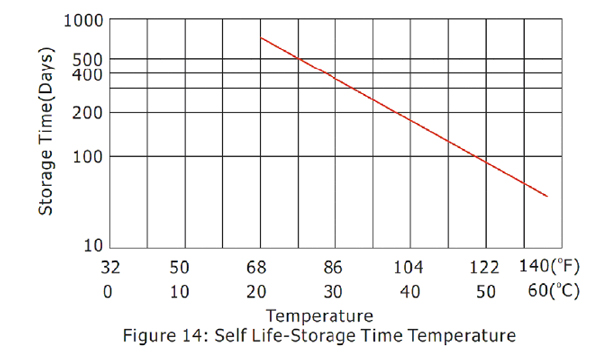

6.5 "Self Life"-storage time vs.temperature Figure 14 shows the time for the capacity to decrease to 50% of nominal capacity at each temperature during storage. If the storage temperature is known, the graph may be used for finding the most useful recommended refresh charge intervals.

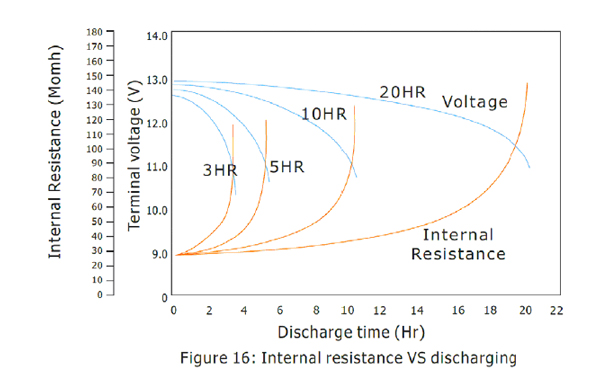

7.Battery Internal ResistanceThe internal resistance of a battery is lowest when the battery is in a fully charged state. The battery internal resistance will be increased gradually during discharge. Figure 16 shows the changing of internal resistance of HX12-7.2(12V7.2Ah) battery during different rated discharging.

|